How are custom sunglasses printed 2023

Custom sunglasses are becoming a popular way for branding. They are an easy way to express your individual style and show off your personality. With custom sunglasses, you can choose the frame, lens type, tint, and even add a logo or design of your own. With the right printing technology and materials, you can create custom sunglasses with logo that will make you stand out from the crowd. In this article, we’ll explore how custom sunglasses with logo are printed and what materials are used in the process. We’ll also look at some of the different types of logos that can be printed on custom sunglasses and how they can be used to promote your brand or business.

How can we print custom sunglasses with logo.let us introduce for you now.

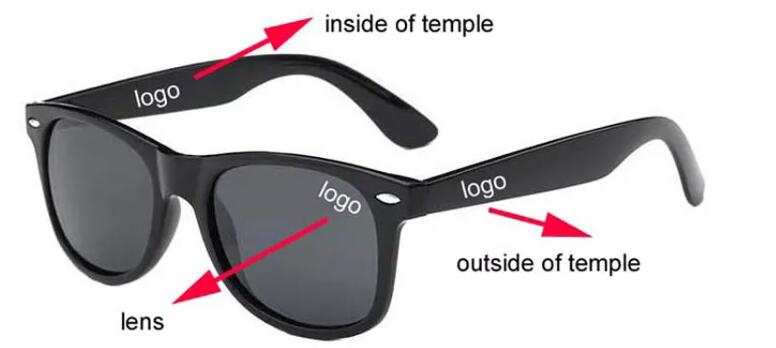

Glasses are made of lenses and frames. The edge area of the lens near the blind spot of the eye usually requires printing, the center of the nose rest of the frame and the side of the leg of the eyeglass are areas that can be printed.The way of the printing on lenses is pad printing, because pad printing can be printed on a smooth and curved surface,

1, ink selection

Ink selection is a very important step in pad printing technology, which is widely related to pad printing technology printing materials. Because the frame is made of metal or plastic, the ink need to match the material. Plastic material need plastic ink,metal material need to use metial ink.

2. Pad printing rubber mover

The pad printing rubber mover is very important in pad printing process. First of all, the shape of the pad printing rubber mover should be able to print to the specified position, followed by small deformation to ensure. Because the printing area of the sunglasses frame is very small, the pad printing rubber mover should be slightly pointed. Through the test, the A7 rubber mover with a cross-sectional area of 38mm is more suitable. The printing effect of A3 rubber mover is also very good, but because the section is slightly smaller, the printing deformation is slightly larger.

3. Steel plate mould

The printing plate mould of pad printing machine is steel plate, and the method of making steel plate is corrosion method. The printing custom sunglasses logo and text of mirror frame and lens are very small, so the size of steel plate does not need to be too large.

the steel plate of 75mm×l00mm and 100mm×100mm can be used, and the longest length of sunglasses custom logo and text is only 20mm, so the steel plate of 75mm×100mm can be used for the custom sunglasses with logo and text.

4. Pad printing machine

The printing area of the glasses frame is small, and it is only the trademark of the printing company, so it does not involve complex sunglasses logo graphics and texts, So The machine should be a small area of monochrome pad printing machine.

5.fixture tool

We also need fixture tool to make sure the position is correct.

All are ready.the machine will move rubber mover to Steel plate mould,then copy the sunglasses logo on the steel plate to the rubber mover.

And them machine will move the rubber mover back to the upward side of sunglasses.then transfer logo to the frame of sunglasses.

Learn more about custom sunglasses by our website ,www.xmnovelty.com.